-

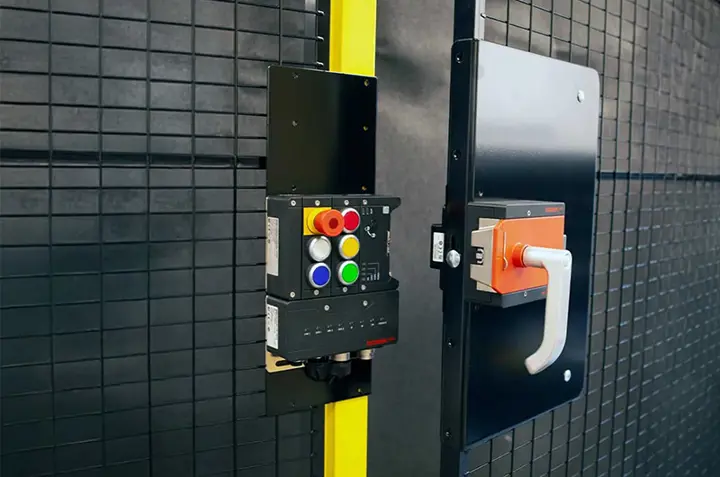

Protezioni perimetrali

Protezioni perimetrali

Axelent è uno dei principali produttori di protezioni perimetrali sul mercato. La nostra missione è fornire sistemi di protezione perimetrale completi, certificati e conformi alle direttive di sicurezza e alle normative europee vigenti. Offriamo soluzioni avanzate per garantire la massima protezione degli ambienti industriali e la sicurezza dei lavoratori in ogni fase della produzione.

-

Magazzino

Axelent è uno dei maggiori produttori di pannelli in rete per industrie e magazzini esistenti sul mercato

Axelent è uno dei maggiori produttori di pannelli in rete per industrie e magazzini esistenti sul mercato. I nostri prodotti e sistemi sono sinonimo di soluzioni versatili e facili da montare in ogni fase, dalla progettazione all'installazione del prodotto finito.

Pareti modulari e strutture a gabbia

Prevenzione della caduta di merci - scaffalature portapallet

Corrimanto anti-caduta

Scaffalatura portapallet in rete

-

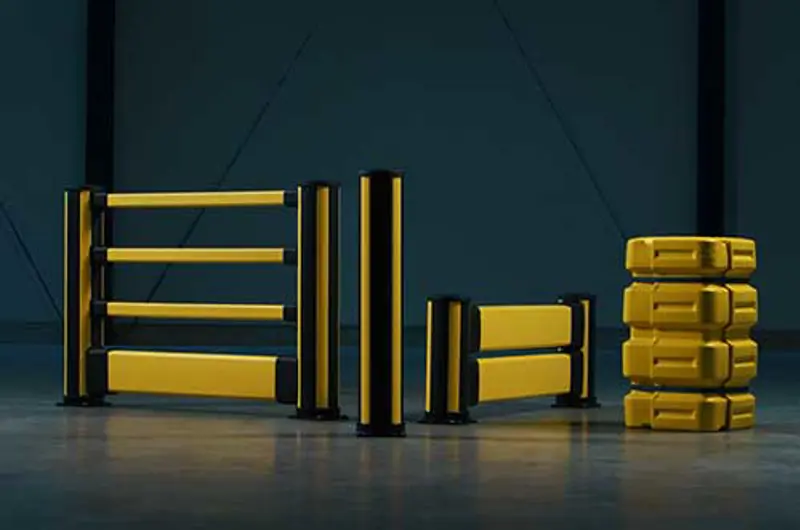

Protezioni antiurto e barriere anti impatto

Protezione dagli impatti

Questa è la nostra gamma di prodotti per la protezione dagli impatti. Abbiamo una gamma completa, dai dissuasori alle barriere pedonali e altro ancora.

-

Passerelle portacavi

X-Tray è il sistema di canaline portacavi di Axelent.

X-Tray è il sistema di canaline portacavi di Axelent. Ha la gamma più ampia del mercato, sia in termini di materiale che di funzionalità. Dal 1° settembre 2022, X-Tray viene prodotto, stoccato e venduto tramite Axelent Wire Tray.